The Department of Biomedical Engineering occupies 29,000 square feet of space at the School of Medicine in the Traylor, Ross, and the Miller Research buildings. Also on this campus is the Translational Tissue Engineering Center (TTEC), which occupies 17,000 square feet in the Smith building. On the Homewood Campus, the Department occupies 34,500 square feet of space in Clark Hall, and 12,000 square feet of laboratory and office space within the Institute for Computational Medicine. Learn more about the different facilities that make up Hopkins BME.

BME Design Studio

The BME Design Studio provides the space and resources for undergraduate and graduate students in biomedical engineering to brainstorm, design, prototype, build, and test solutions to real-world clinical and global health challenges.

Tissue Culture Facilities

The Cell and Tissue lab is a BSL-2 facility that supports educational research and design work within the department. This facility is on the first floor of Clark Hall and requires specialized training.

WSE Manufacturing

WSE Manufacturing is capable of producing everything from the simplest parts for an undergraduate design project to the most sophisticated elements necessary for advanced scientific research.

WSE Microfabrication Lab

The lithography and fabrication facility in Clark Hall is established as a multidisciplinary focus point at the Homewood campus to facilitate research and education for undergraduate and graduate students in the area of microfabrication and system integration.

School of Medicine Microscope Facility

The Johns Hopkins University School of Medicine Microscope Facility has provided light, fluorescence, and electron microscopy services to over 400 users a year throughout Johns Hopkins University and the local area. It is one of the largest and most popular facilities in Baltimore providing microscopy and imaging services.

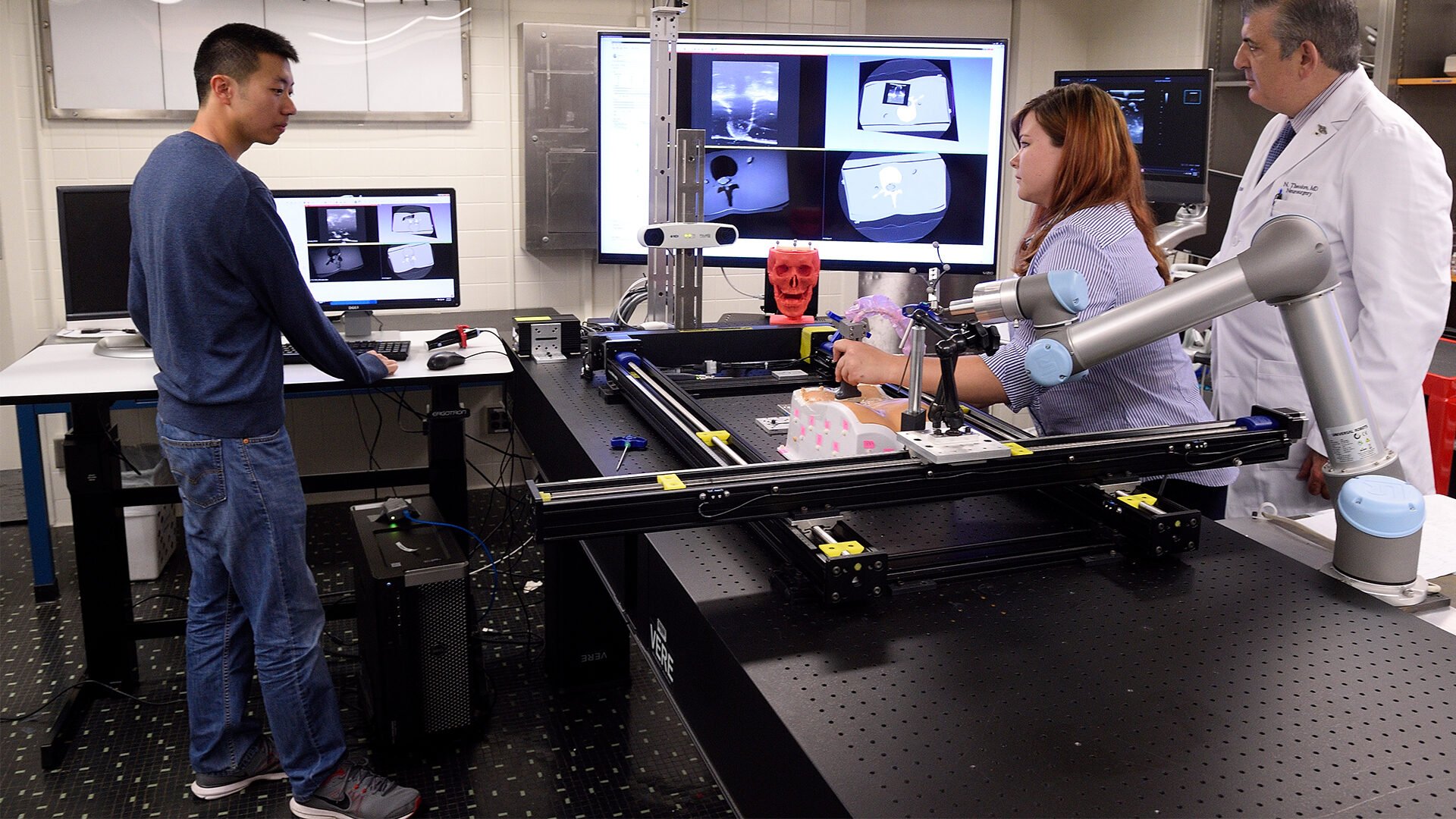

Carnegie 3D Printing Facility

The Carnegie 3D Printing Facility creates material and digital models of medical conditions for education, patient-specific prostheses, and surgical guides as well as functional device prototypes. This facility helps medical practitioners, researchers, and students create sophisticated models of their ideas. Using the Polyjet, FDM and SLA 3D printers, a wide variety of material properties and aesthetic qualities can be imparted to the design. Applications for 3D printing range from novel engineering devices to anatomical models for surgical training, planning, and patient education.