Autologous fat grafting is a minimally invasive surgery procedure that uses liposuction to harvest a patient’s own fat. The fat is processed to remove unwanted contaminants — such as oil, blood, and excess fluids — and prepared for reinjection to structurally repair or enhance different areas of the body. Fat grafting is used for both cosmetic and reconstructive procedures, including facial rejuvenation and breast reconstruction.

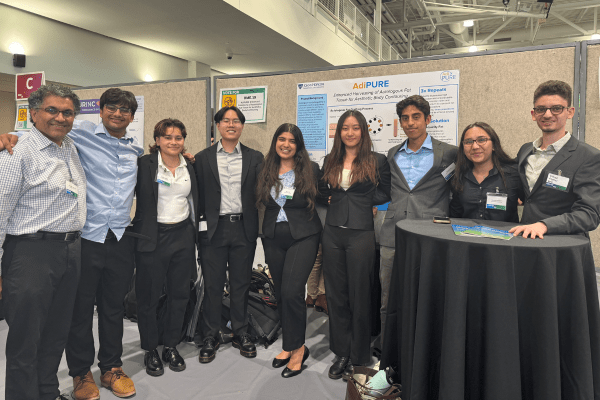

To make fat grafting more successful, a group of biomedical engineering students in the Design Team program has developed a novel system for standardizing the production of high-quality fat for reinjection.

According to Kevin Nguyen, leader of the AdiCleanse Design Team, there is currently no universal method for processing aspirated fat and most techniques produce inconsistent fat quality across procedures. Injection of poor-quality fat, with compromised structural integrity and regenerative ability, can result in volume loss at the recipient site, thus requiring additional corrective procedures for the patient to achieve their desired outcome. “In contrast to existing methods, our system processes the fat as the plastic surgeon is using liposuction, purifying it in parallel and preparing the fat for extraction into syringes for reinjection into the body,” said Nguyen.

Additionally, the system can be applied on small and large scales. Smaller scale uses include facial rejuvenation and scar reduction; larger scale uses include breast reconstruction and gluteal augmentation.

A streamlined system will open further improved applications for autologous fat grafting, such as in orthopedic procedures where the regenerative properties of autologous fat are now being captured to accelerate tissue healing, adds Nguyen.

The possibility for additional applications of their system is a major motivator for the team. “Over one million fat graft procedures are performed annually across the world, and there are many untapped sectors that we could innovate in,” said Nguyen.

The team chose to tackle a problem with both biological and mechanistic components, allowing them to explore the field of cellular and tissue engineering. They had to work together to utilize both theoretical and clinical information to develop a final solution. “After discussions amongst ourselves and with our mentors we have been able to converge on a solution that is both clinically relevant, but also stems from the scientific discoveries being made,” said Nguyen.

For the AdiCleanse team, the Design Team experience has not only been an academic exercise, but has provided the students a direct connection to the engineers, physicians, and scientists who are directly involved in many of the technologies and scientific discoveries that impacted the development of their project solution.

“Professionally the Design Team experience has opened many doors for us and allowed us to connect and network with many key opinion leaders in the field; bringing expertise from both the bench and the bedside to our project,” said Nguyen.

The AdiCleanse team also includes Jayvik Joshi, Serena Banghar, Meera Bhat, Farid Shahid, Ethan Abelev, Miranda Qing, and Armelle Varillas.